CAM CZ is your expert in chip machining, both dry and wet methods. We offer comprehensive solutions, from design to execution, tailored to your specific needs. Together, we achieve excellent production quality. Additionally, we provide sorting services for the final product, using both measuring instruments and visual inspection.

Comprehensive Service Offering.

We provide a wide range of services, from product design to thermal and surface treatments. Our offerings include material management, finding optimal production solutions, and logistics management across Europe.

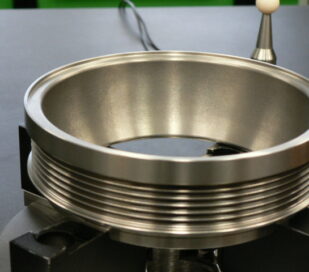

Product

We specialize in products with dimensions of 250 mm (width) by 120 mm (height) and a maximum weight of 15 kg. We also handle raw material cutting on CNC machines and can upgrade our equipment based on customer needs.

Order and Delivery Management

We offer consignment storage, direct sales, and can manage full production processes, taking full responsibility for all supplier activities.

Feasibility Study and Prototypes

Feasibility study and implementation of the preliminary project for serial prototypes.

Logistics

Logistics management in all European countries.

Management of Raw Materials and Surface Treatments

Direct management of raw materials through the sourcing and selection of certified suppliers based on quality/cost/service requirements. Our suppliers are capable of providing materials such as steel, grey cast iron (GG25), and ductile iron (the range of materials can be more extensive). For surface treatment suppliers, we have experience with applying micron layers ranging from 15 to 80 microns. We use a cataphoretic coating process—either continuous or step-by-step, using BASF or PPG paint. We can also provide other types of surface treatments, such as ZnNi.

Sorting of Final Products

Based on our experience with 100% visual inspection in our own production, we offer this service to potential customers. We handle all logistics and set up the necessary measuring devices and visual inspections according to customer requirements and technical documentation. This service is available for both mass and small-batch production.

Optimization of Production Solutions

We implement the most efficient manufacturing solutions, including through specific investments when necessary.

We value our customers.

Quality. Control. Flexibility. Competence.

At CAM CZ, quality is the highest priority. Our manufacturing processes are governed by strict reference standards, we use precise measuring tools, and we emphasize the continuous education of our staff. Control systems, combined with accurate inspection procedures, ensure the high standard of quality in all our products. At the same time, we maintain the flexibility and competence you expect from a leading industrial partner. Thanks to the synergy between our expert teams, we can offer products that fully meet the contractual conditions and requirements of our clients.

The 4 Core Pillars of Our Company.